In general terms, pulleys are all about efficiency and there are three basic considerations that will affect the sheave or pulley wheel efficiency:

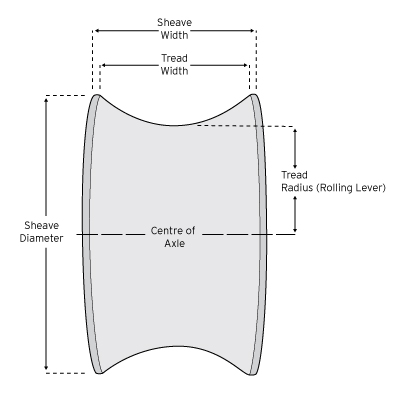

- Tread radius size. The leverage is a function of the tread radius so the larger the 'rolling lever' the easier the sheave rolls.

- Efficiency and type of bearing - bushing or roller.

- Engineering quality and the attention to detail in terms of tolerances.

A compact 'high-spec' well engineered pulley could achieve a similar level of efficiency as one with a larger tread radius that isn't as well made.

DMM's original and classic pulley has a sheave with a relatively deep groove/tread pattern in relation to its width, a pre-lubricated Oilite® bushing (bronze sleeve that spins around the stainless steel spindle) and aluminium side-plates.

In terms of use, so long as the rope is running fair - not making contact with the side-plates - it is a good general purpose pulley. But that ideal isn't always possible when using a torsion resistant anchor.

If for any reason, the pulley can't move to align itself in the best orientation to avoid the rope rubbing against the side-plates, then there is a loss of efficiency due to friction. And with a deep tread the rope will also have a tight bend radius over the edge of the side-plate.

Pinto Rig Pulley and Bat Plate being used for swift water rescue.

Pinto Rig Pulley and Bat Plate being used for swift water rescue.In partnership with Treemagineers, DMM developed their hot forged Triple Attachment and Pinto pulleys with specifically designed features to ease this issue. On the Triple Attachment Pulley the side plates are radiused and polished to give a smooth edge. They are also angled away from the sheave (fair-lead flare) to give an improved bend radius if the rope isn't running fair.

This pulley also has a relatively wide and shallow tread pattern with a low side-plate so the rope can run at more of a deviation before it hits the side plate and loses efficiency. Put another way the rope can run at a higher efficiency for a greater deviation than with a standard pulley. When it does hit the side-plate there are flares and rounded surfaces to minimise the loss of efficiency.

The Pinto shares these features with the Triple Attachment Pulley but takes the concept further, resulting in very obvious fair-lead flares and curvy textile friendly side-plates.

The slightly larger Pinto Rig (16mm max rope diameter) has two gains with a larger tread radius and a high efficiency roller bearing giving ultra smooth operation. The Triple Attachment Rapide Pulley also benefits from the addition of a sealed-for-life roller bearing, rather than a bushing.

DMM pulleys continue to evolve and at the 22nd Deutsche Baumpflegetage (German Tree Care Conference), May 5th - 7th, DMM will be launching the next generation.